Week 9 Update

For this week we decided to continue on with our design of the junction. David has been CADing up some ideas. We were worried about the spacing between the track and between the support columns within the inner portion of the guideway. As of now, we are working with the cross-section shown in the image below. This track is made of three key tubes that are roughly 2x8" (top and bottom) and 2x4" (vertical). After some discussion with Ethan and Professor Furman we are thinking of making the top and bottom sections 2x6". This would lower the cost of materials.

Image 1 (above): cross section we are planning on using for our track

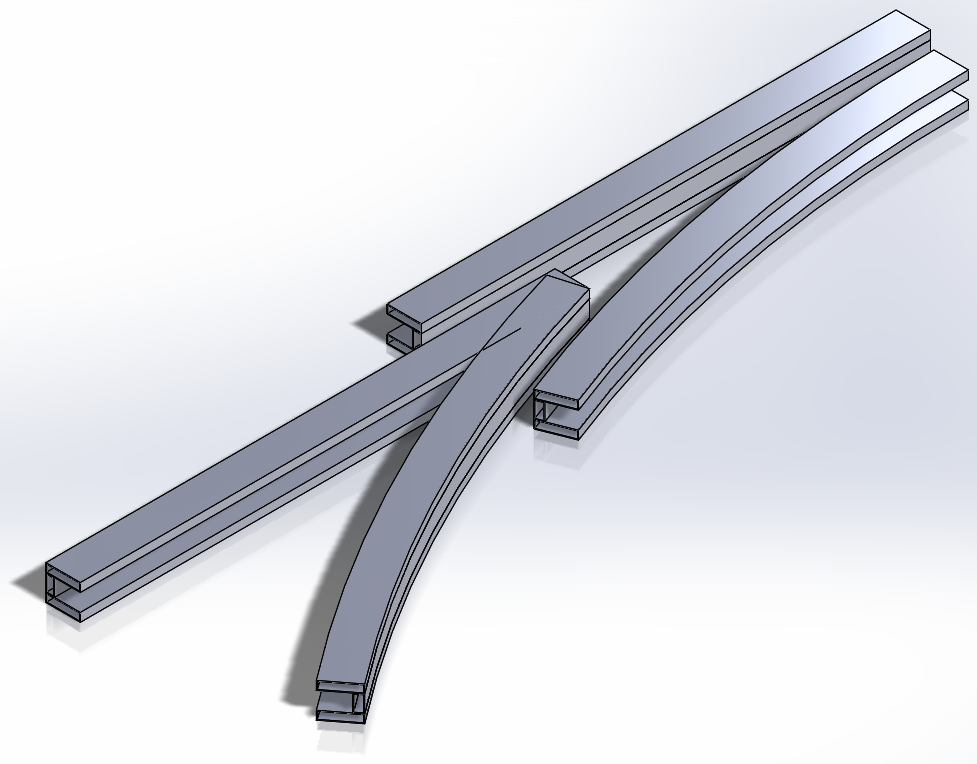

The junction design we are currently working with requires bending (seen in image 2). After some discussion, we are thinking of implementing welding straight sections rather than bending. This is due to manufacturing costs. For the next week or so, we will be researching manufacturing costs for both, but are leaning more into welding straight sections to form a curve (image 3).

Image 2 (Above): Junction design that requires bending of our rail

Image 3 (above): Welding of straight sections. A thin metal sheet would be attached on the inside portion of the curve to create a smoother surface.

Another thing that we are focusing on this coming week is working with the solar team to get an FEA for the column structure on which the solar panel structure will be mounted. When we tried to perform FEA on the provided files from Furtan, we had some issues due to bad CADs. However, we are hoping to rebuild these so we can provide the Solar team with something soon.

We were finally able to present this week, Presentation #2 is posted on our week 8 blog!

We are currently on track with finalizing our design for next semester and will be looking into manufacturing costs very soon!

Full Scale Guideway Team,

ReplyDeleteGood job so far! A few questions I have...

1. Are you planning on using the vertical support and footing designs from the previous year as shown on your first slide of your presentation 2?

2. What about the horizontal support column? Will you use the previous design to aid in your fabrication?

Excited to see the individual parts come together.

Be sure to practice on the TIG welder in the shop. Ensure it has Argon gas, the water tank is at a good level, and that the tungsten tip is sharp and ready to go...

Here is a google doc that was created by last year's team giving detailed instructions on how to use the TIG:

https://docs.google.com/document/d/1MoDoLIqfya8EcoGuZrEmABt60QF7cUu7ISXmnKbllFI/edit?usp=sharing